Behind the scenes

Precision in production!

Tekno is perfectionist. We pay a lot of attention and time towards good preparations in which we set up the exact specifications of the model to be produced. Only then can the process of translation from “original” to “miniature” begin. For that we work together with partners at home (Holland) and abroad and theyuse the most modern tools like, moulding tools and computerized machines for drilling, milling and turning. The models are painted in a high-pressure cabin, that meet strict environmental requirements and guarantees a perfect result.

Texts, striping and other decorations are placed on the model through tampon and screening, so the quality and sustainability is guaranteed. Once the parts are then assembled, your model truck gets its definite shape.

Who is Tekno and what do we do? In this video we take you into the world of Tekno and how our beautiful models are produced:

Product development

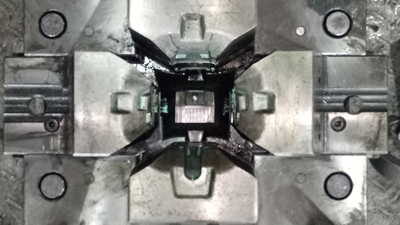

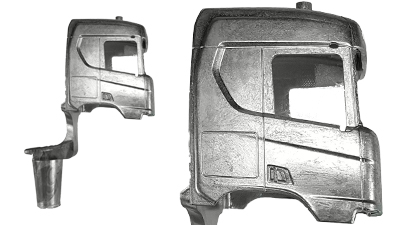

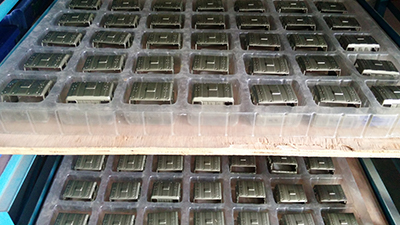

Before the production of the model can be started, the parts must be developed. All the components are designed and developed by Tekno. Most of the parts are made by injection mould technique. To obtain a perfect result, however, durable, high-quality and expensive moulds are needed. These are steel casting moulds, in which under very high pressure liquid material are injected.

To make such moulds high technical skills are required, and Tekno is equipped with the needed expertise. 3D drawing techniques are being used. Developing the product is a accurate and costly process and to make a model, many moulds are needed. For instance, 15 moulds are needed to make a single truck.

After testing the moulds and the samples of the first coating, the components can be filled in.

This is the first step in the production of a Tekno model.

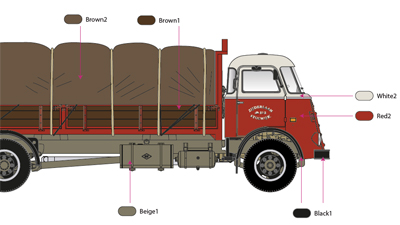

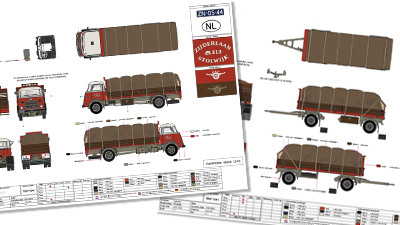

Design Concept Drawings

Based on the taken photos or by using existing digital files, a detailed drawing is made, which perfectly corresponds with the wishes of the client. We use various graphic programs, such as, Adobe Illustrator, Adobe Photoshop and Auto Text Inventor Professional. When the initial drawings pass the customer’s approval, we will proceed to the next stage: preparing the production of the model.

Production Preparation

Before the model goes into production in China or the Czech Republic, we naturally need to ensure that the customer’s wishes are perfectly realized during the production. We do this by constructing a sample model, with which we precisely and step-by-step describe every stage of the process so that everything would run smoothly during the production of the model in one of our factories.

Production China and the Czech Republic

The production of a Tekno model takes place in China or the Czech Republic. Our sister companies in these countries can offer a whole lot of possibilities, which consequently enables Tekno to provide its customers with a wide range of products with the best quality.

Final Check and Delivering

After the production of the model is completed, the models are sent back to Tekno in De Lier by road, sea or air transportation. After an extensive final inspection is done, the models are released to be extradited to the different types of customers, such as trucking companies, truck manufacturers, dealers and individuals (collectors).